At present, ferrous metallurgy

is mostly aimed to increase products quality without rapid expansion

of facilities but not to grow material output as the situation has

been for several years. It requires to create basic material

consuming less metal, however having higher mechanical properties

because of adding alloying components to the melt. Sometimes such

components can be included immaculate structure, however as a rule,

as ferro compounds, i.e. iron composites with alloying components.

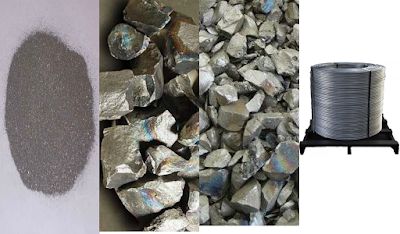

Ferro titanium is one of the most widespread and effective ferro

alloys.

Ferro

titanium is the alloying addition consisting of iron and titanium

with the minimum titanium weight content of 20 % and the maximum

weight content of 75 % manufactured by reduction or melting.

Assembling of titanium combination ingots and plant items

additionally brings about era of metal scrap. Some scrap is reviewed

sub-standard as it can't be reused to charge materials for softening

titanium amalgam alloy because of oxidation degree, squeezes and

forge laps.

In

order to use substandard titanium scrap, the manufacturing process

for high-grade ferro titanium has been developed and mastered. It is

based on melting ingots of low-melting eutectic (1085˚) in the

titanium-iron system with 65-75 % of titanium. This process allows

melting scrap in the form of solids, bundle and briquetted clippings

and loose crushed titanium chips. Obsolete titanium scrap has become

more utilized lately.

In

order to manufacture ferro

titanium cored wire with the

specified amount of additions, all titanium scrap is sorted based on

alloys and alloy groups. Most applications require controlled amount

of Carbon and Aluminum in the final Ferro Titanium produced. To

ensure the controlled Aluminum and Carbon percentage the scrap

selection and testing is imperative. The source of the scrap and

elaborate testing of the scrap is important before making the raw

material batches for the heat.

High-grade

ferro titanium is manufactured by M/s Bansal Brothers by induction

and electro-slag remelting. Induction ferro titanium is produced in

channel-type induction furnaces in the form of a flat taper ingot

with the weight of 500-550 kg. Each heat is subject to chemical

analysis. Titanium is an active element and takes nitrogen and oxygen

as a result of air interaction. That is why it is required to protect

the melt from gas saturating.

Thus,

following things are extremely crucial to control the quality of

Ferro Titanium to be used for specific applications:

1.

Scrutiny and selection of the correct Titanium and Fe scrap

2.

Sample testing during production

3.

Controlling Oxygen & Nitrogen, Titanium being an active metal